Laser sandblasting & drilling machine

Mobile multi-function for high-definition pattern creation

Mirror sandblasting with high-definition pattern creation

Precision glass surface carving and etching

High-precision glass drilling and perforation

Selective mirror paint removal technology

With 5-axis linkage motion, pattern joins are flawless—Y-axis accuracy controlled within 0.2mm and X-axis within 0.2mm. The user-friendly software can be learned by computer novices in just 3 hours.

Compatible with multiple file formats including .PLT, .DXF, .AC6, and .JPG. Delivers rapid carving speed with fine, uniform dots—completing in only 2-3 minutes. Energy efficient at approximately 1 degree per hour, operating on 220V 50-60Hz power.

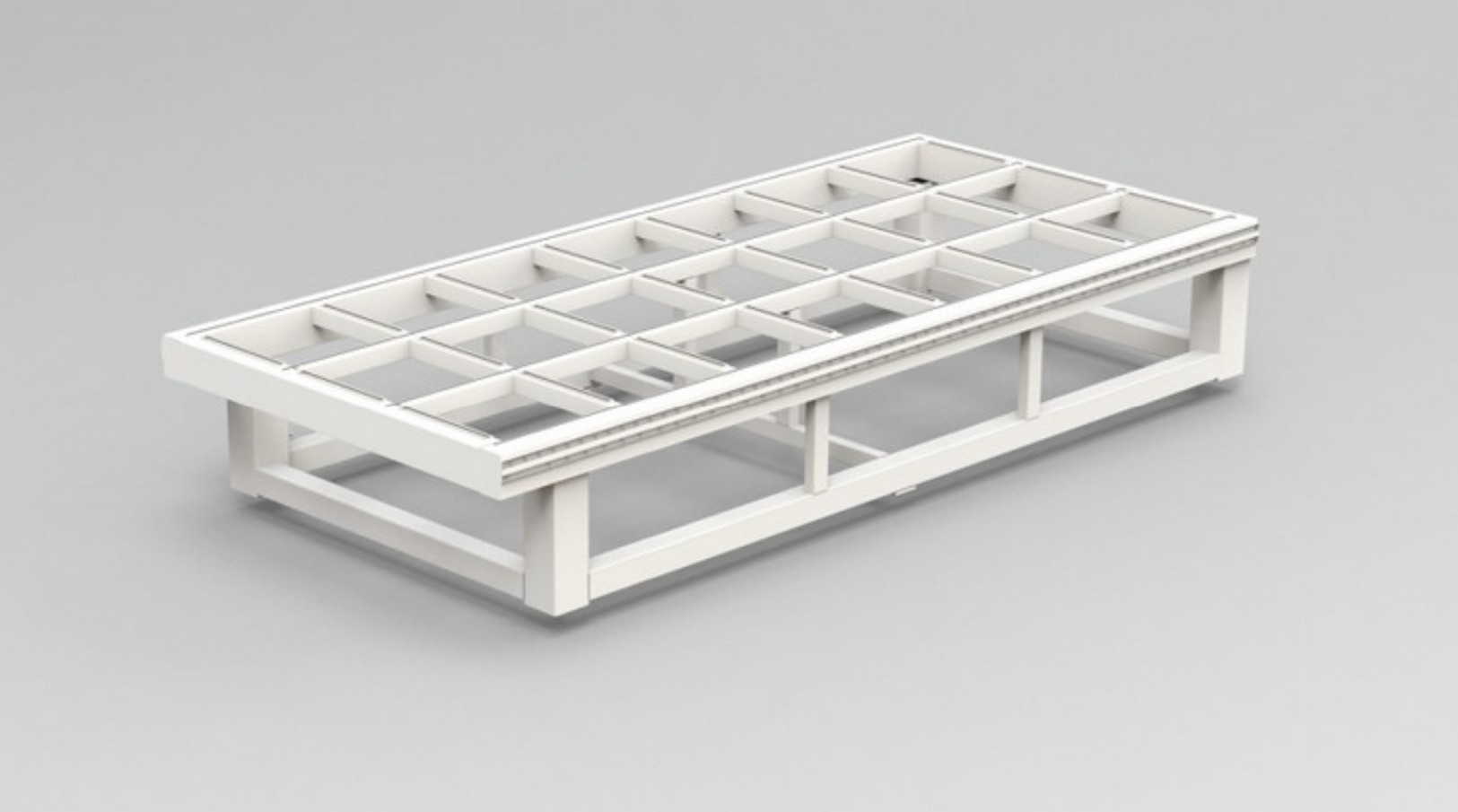

Base Frame: Precision Engineering for Ultimate Stability

Crafted with a high-strength welded steel structure, the base frame undergoes thorough stress relief through annealing and vibration treatment before and after rough machining. Final finishing is completed with a 5-axis CNC machining center, effectively eliminating stress from welding and processing. This ensures exceptional structural stability and long-term durability of the machine.

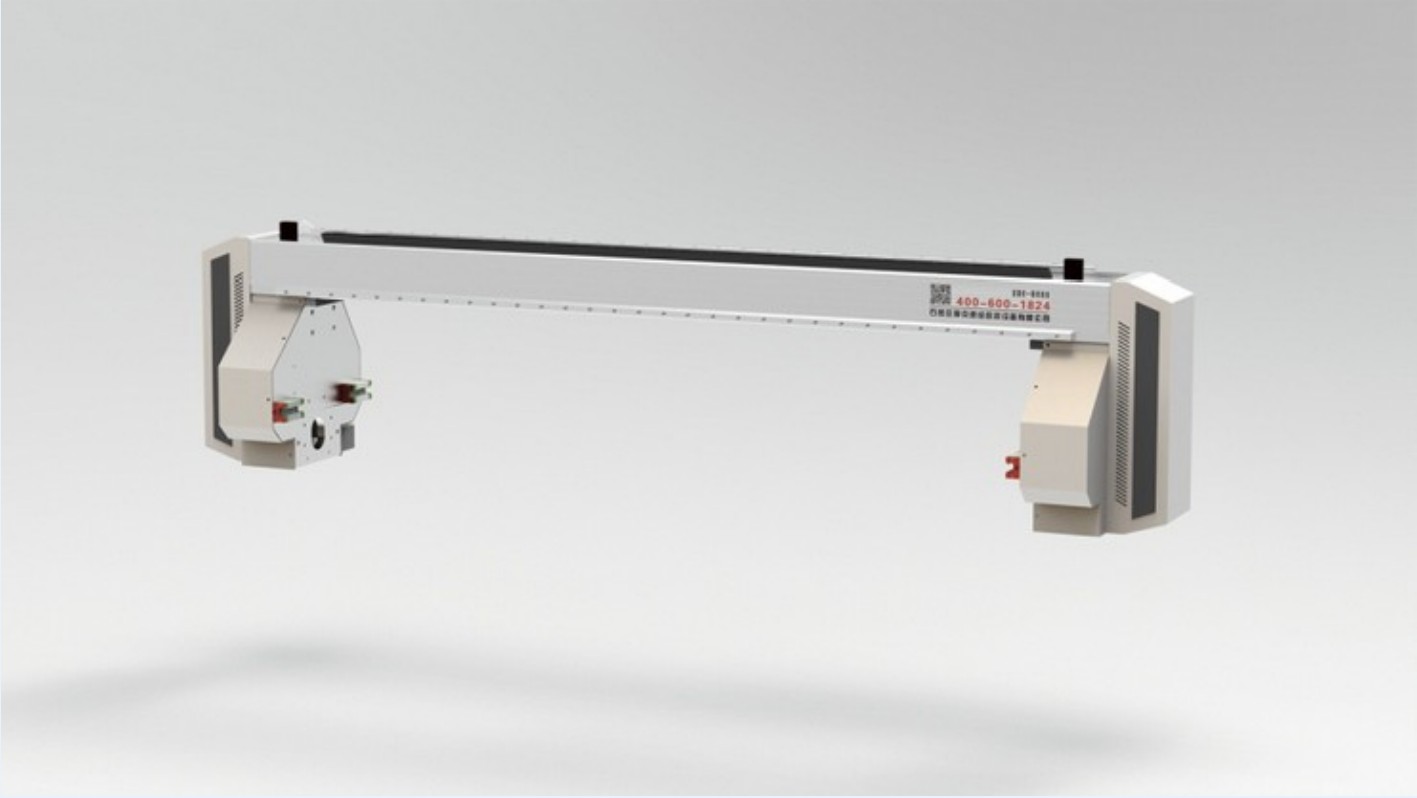

Crossbeam: Lightweight Design with High Rigidity

The crossbeam is made from aerospace-grade aluminum alloy, featuring a box-type structure for superior strength and dynamic performance. Following stress relief treatment, it is precision-machined to ensure dimensional accuracy and overall structural integrity. This design guarantees stable and reliable operation, even at high speeds.

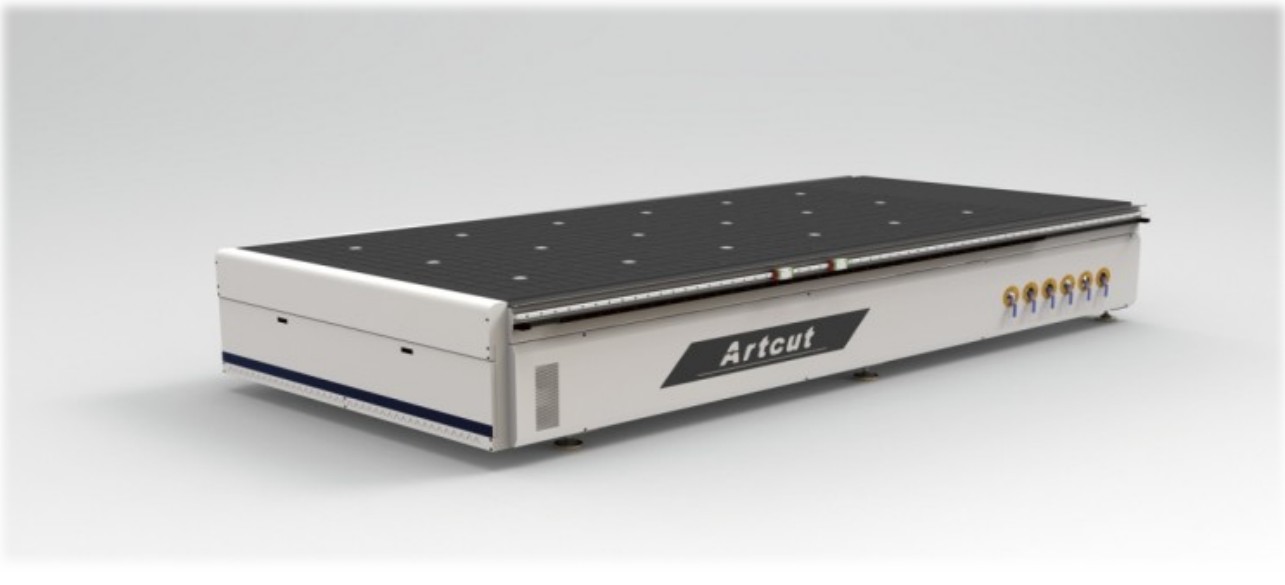

Worktable: Durable, Refined, and Cost-Efficient

The worktable is independently designed and structurally separated from the main frame to ensure stability. Its support frame and guide rails form a modular, easy-to-maintain structure. The surface is made from a specialized anti-rust transmission material, resistant to long-term wear and surface damage during continuous engraving—effectively reducing customer maintenance and operating costs.

5-Axis Precision

5-axis linkage motion for perfect pattern joints with X/Y axis accuracy within 0.2mm.

Rapid Processing

Complete one smart mirror within 2-3 minutes for maximum efficiency.

Energy Efficient

Low power consumption of only 1 kilowatt per hour (220V 50-60HZ).

User-Friendly

Simple and flexible software operation, learnable within 3 hours even for computer novices.

Format Support

Compatible with EPS, PLT, and DXF file formats for versatile design input.

Versatile Application

Suitable for all metal materials with ability to carve any pattern or design.

Technical Specifications

- Laser power/Output power

- 140W optional

- Operating mode

- laser pulse

- Theoretical laser life

- about 80,000 hours

- Laser center wavelength

- about 1064nm

- Appearance size

- 3000*2100*800mm (length,width and height)

- Laser preheating time

- 1min

- Maximum processing range

- 1200*2400mm

- Theoretical maximum speed

- 12,000 points/sec

- Power requirement

- 220V 50-60HZ

- Spot diameter

- 6-8mm

- Cooling method

- water cooling

- Frequency range

- 50-170KHZ

- Motion form

- five-axis linkage

- Weight

- about 900KG