Smart Mirror Laser Processing Technology

As consumer interest in smart home products increases, smart mirrors are gaining recognition in the market and gradually becoming part of high-end home decoration. By 2024, renowned institutions estimate that the global smart mirror market will reach $4.35 billion. Smart mirrors combine tradition with technology, and personalized demands are gradually rising, further integrating into daily life.

The production of smart mirrors relies on mirror paint stripping, sandblasting and other processes. Traditional mirror paint stripping and sandblasting processes struggle to meet consumers' personalized customization needs. Laser processing offers advantages such as flexible design without masks, high production efficiency, and environmental pollution-free operation, making it the preferred method for smart mirror processing. The Moke laser sandblasting machine can complete multiple process flows including mirror sandblasting, paint stripping, and drilling in one go, and can also solve large-format production splicing problems through galvanometer and axis linkage equipment solutions.

Sandblasting, Paint Stripping, and Drilling - All in One Machine

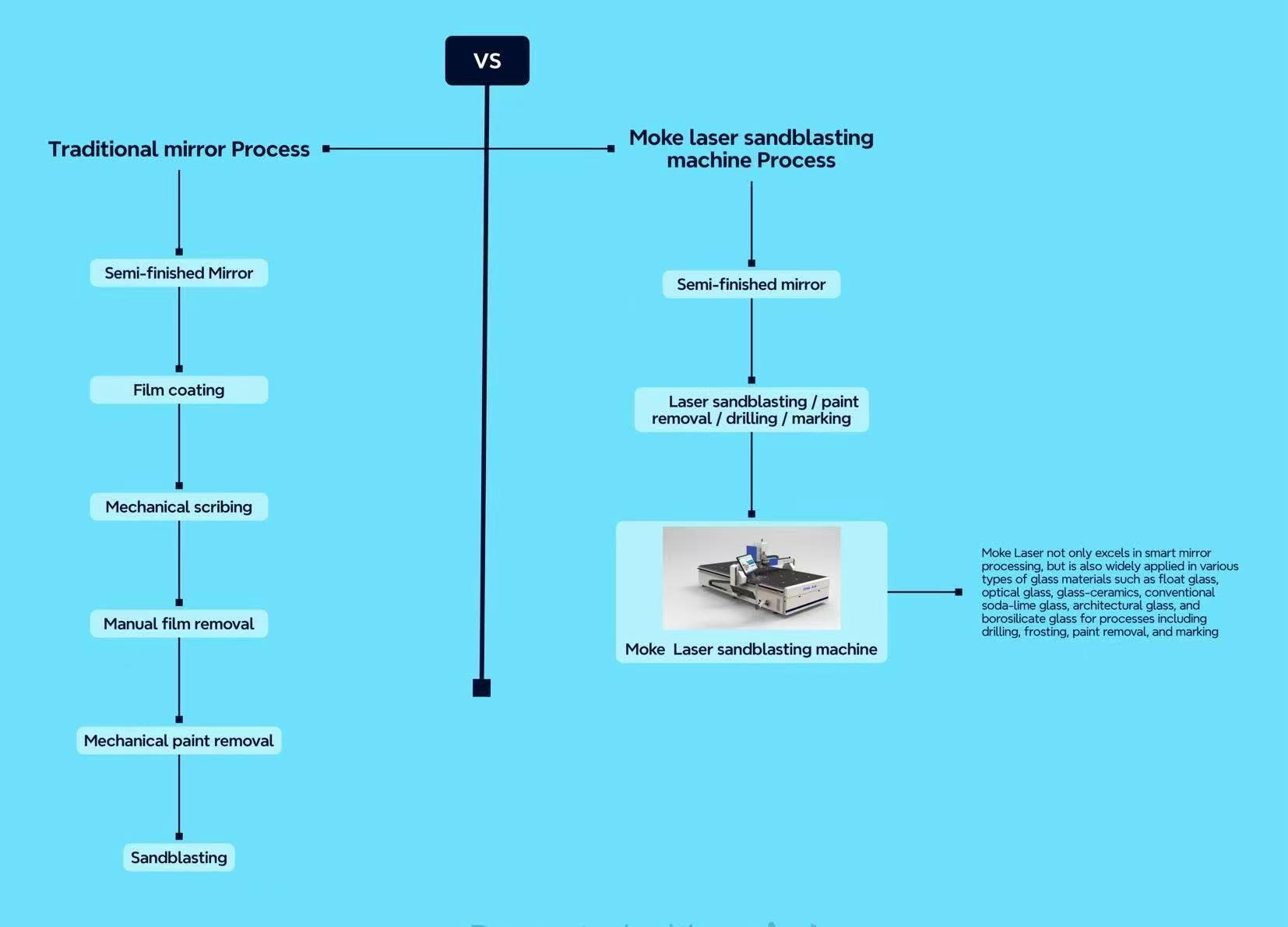

Traditional mirror processing methods involve complex and cumbersome procedures, requiring covering first, then engraving, followed by manual film removal, paint removal, and finally sandblasting. Later, lasers gradually replaced physical processes, but still required three steps to complete processing requirements. The Moke laser sandblasting machine needs only one step to complete the process, reducing procedures, saving labor, and being more environmentally friendly with no consumables.

Mirror Processing Comparison

Laser processing is a high-precision, non-contact processing technology that is not only simple to operate but can also meet complex and refined process requirements. With high peak power (Pp>200kW), equivalent to 20 times that of conventional fiber pulses, and good beam quality (M<1.3), its advantages in smart mirror processing are mainly reflected in the following aspects:

Key Advantages

1. High Processing Efficiency

Provides high peak laser pulses that can release extremely high energy in an extremely short time, making the processing rapid, and can be combined with automation to achieve large-scale production.

2. High Processing Precision

Through precise control of each laser pulse's energy and small focused spot size, it achieves fine processing of smart mirrors. While meeting complex processing requirements, it avoids damaging the sensitive structures and components inside smart mirrors.

3. High Processing Stability

With high peak power and short pulse duration, the heat-affected zone is small, reducing thermal damage to other parts of smart mirrors during processing. Non-contact processing does not cause mechanical pressure or wear on smart mirror surfaces, resulting in better processing effects.

4. Unlimited Creative Flexibility

Any pattern can be processed without templates - computer editing allows for immediate use, making it very suitable for personalized requirements.

Wide Application Range

The Moke laser sandblasting machine not only performs excellently in smart mirror processing but is also widely applied to various glass materials including float glass, optical glass, glass-ceramic, conventional soda-lime glass, architectural glass, and high borosilicate glass for drilling, texturing, paint stripping, marking and other processes, meeting diverse material processing requirements.